Fossil Fuel Vs Bio Based Plastic – What is the Difference?

Generally speaking, plastics fall into two main categories, Fossil Fuel and Bio Based Plastic. This refers to the source material used to make plastic bags. While there are subcategories, the plastic we use everyday will typically be made of one of these two.

Fossil Fuels vs Bio Based: The Difference Between Plastics

Plastics are everywhere in our modern world, used in everything from packaging to clothing to automotive parts.

But not all plastics are created equal.

Most of the 300 million tons of plastic produced annually comes from fossil fuel sources. However, interest is growing around alternatives derived from renewable biomass like plants instead of oil and gas. This article will examine the key differences between traditional fossil fuel based plastics and emerging bio-based and biodegradable plastics.

The Fossil Fuel Foundation

- Fossil fuel-based plastics:

- Made from petroleum (oil) and natural gas (methane).

- Examples include polyethylene (PE), polypropylene (PP), polystyrene (PS).

- Most common and widely used type of plastic today.

- Not biodegradable, persist in the environment.

Most of the plastics we commonly use today are made from fossil fuels like petroleum and natural gas. These conventional plastics include polyethylene, polypropylene, and polystyrene.

The building blocks of common plastics like polyethylene, PVC and polystyrene are derived from fossil fuel feedstocks. These include natural gas, oil and coal. Refining and chemical processing transforms these fossil sources into inexpensive base chemicals like ethylene and propylene to manufacture plastic resins.

While very prevalent, these traditional plastics made from oil and gas do not biodegrade. Instead they persist for centuries after disposal, remaining intact in landfills and the environment.

Unlike some newer bioplastic alternatives made from plants, conventional plastics made from fossil fuels do not break down naturally.

So once produced and used, they continue accumulating as waste. The durability and non-biodegradable nature of traditional plastics made from petroleum and natural gas pose major challenges for sustainability and effective waste management.

Fossil fuels provide a cheap and abundant source for plastic production. However, there are sustainability downsides. Fossil plastics have a significant carbon footprint from extraction, refining and manufacturing. Producing plastics accounts for 4-8% of the world’s oil production and climate impacts. And plastic waste persists for centuries, contributing to environmental problems.

Exploring Bio-Based Sources

- Bio-based plastics:

- Made from renewable biomass sources like plants.

- Examples include bio-PE, bio-PP, PLA (cornstarch), cellulose.

- Represent a small but growing share of total plastics.

- Some are biodegradable or compostable.

Bio-based plastics provide an alternative by using renewable biomass as raw material instead of finite fossil fuels. Feedstocks can include corn, sugarcane, cellulose from plants and even waste materials like fruit peels. The building blocks get converted into polymers through processes like bacterial fermentation.

These bio-based plastics include biodegradable materials like PLA (from cornstarch) and cellulose.

Other examples are bio-PE and bio-PP which are essentially plastic polymers made from plants instead of petroleum. Though bio-based plastics currently make up a small percentage of overall plastics production, they are a growing segment.

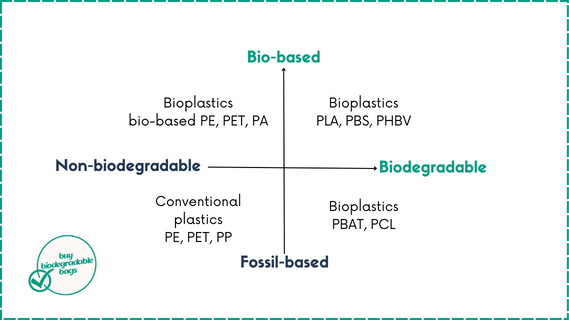

However, bioplastics are a diverse category with tradeoffs. Not all bioplastics biodegrade, and biodegradable plastics vary greatly in longevity and required conditions. That’s the importance of differentiate between biodegradable and nonbiodegradable.

Some bio-based plastics are engineered to be biodegradable, breaking down through natural processes.

The plant origins and modified properties of some bio-plastics enable them to be compostable and break down at end of life, unlike traditional plastics. However, bio-based does not automatically equal biodegradable.

Overall, bio-based plastics provide opportunities to rely less on finite fossil fuel resources and reduce plastic waste accumulation through improved biodegradability. But more innovation is needed for them to compete with conventional plastics on cost, performance and scale.

To re-cap, the two main categories of plastics are:

- Conventional plastics derived from fossil fuels

- Plastics derived from renewable plant sources

The key distinction is the raw material ‘feedstock’ used to produce the plastic polymer. Most plastics fall under either fossil fuel-based or bio-based.

Contrasting Manufacturing Footprints

Fossil fuel plastics follow a multi-stage manufacturing process. First oil and gas is extracted, then materials like naphtha are refined through cracking into building blocks like ethylene. Finally, chemical processing polymerizes these hydrocarbons into plastic resins.

Bio-plastic production also starts with extracting feedstock materials, in this case through agriculture. Then fermentation or other processes derive required monomers like lactic acid. Finally, polymerization creates the bioplastic resins suitable for conversion into plastic products.

Fossil plastic production is mature large-scale industry. Bioplastics are a niche market constrained by technical challenges, limited feedstocks and higher costs. This makes rapid scaling difficult currently.

Performance Tradeoffs

Fossil fuels can produce the full gamut of plastic types, from durable long-chain polymers suitable for diverse products to plastic films and wraps. Different chemical compositions enable varied performance properties.

Bio-based plastics have more limited applications so far. Some mimic conventional plastics like PE and PET. But factors like strength, durability and resistance are harder to match, especially for biodegradable bioplastics. This restricts usage to more specialized roles.

Divergent Environmental Profiles

Fossil plastics have sizable carbon footprints from resource extraction through manufacturing. Low recycling rates mean most plastic becomes waste persisting for centuries. This contributes to problems like ocean plastic pollution.

Bio-based plastics aim to reduce carbon impacts by utilizing renewable resources. Biodegradable plastics could lessen waste accumulation long-term. But proper commercial composting is required, otherwise bioplastics still create microplastic pollution. Some life cycle analyses show tradeoffs.

Economic Challenges for Bioplastics

Inexpensive and abundant fossil fuel feedstocks have historically meant low costs for conventional plastics. Bioplastics currently cost anywhere from 2-10 times more than comparable fossil-based plastics. Producing at small scale limits economic feasibility.

Rising oil prices could make bio-based plastics more cost competitive long-term. Regardless, scaling up production is essential to make bioplastics affordable alternatives able to displace substantial shares of fossil-based plastics.

In short, while bio-based plastics show promise as renewable alternatives, they remain a developing technology with some limitations. As public awareness and demand for sustainable materials grows, they are likely to claim larger market share. But consumption habits and waste management, not just material sources, need considering in tackling plastics sustainability.

Additional types of plastic

In addition to the two main categories of fossil fuel-based and bio-based plastics, there are other types of plastics:

- Recycled plastics: Plastics made from recycled materials collected through waste recovery systems. Examples are rPET (recycled PET plastic) and rHDPE (recycled HDPE plastic).

- Biodegradable plastics: Plastics designed to completely break down into natural materials in the environment. Can be bio-based or fossil fuel-based with additives. PLA (polylactic acid) is a common type.

- Compostable plastics: Break down into compost in industrial facilities. Must meet certain standards like EN 13432. Examples are PLA, PBS, and starch-based plastics.

- Oxo-degradable plastics: Conventional plastics with additives to accelerate fragmentation in the environment. EPI’s TDPATM additive produces oxo-biodegradable plastics.

- Smart/functional plastics: Plastics with advanced functionality like self-healing properties, conductivity, sensors, drug delivery. Still a niche category.

So while fossil fuel and bio-based plastics make up the vast majority, there are some other specialty plastic categories to consider as well. The distinctions have to do with their properties, lifetime, and origins.

New plastic technologies are emerging all the time and solutions are constantly being explored.